Why Use

No More Props is a single tool that replaces multiple pieces of equipment and so cuts job time in half and saves money.

You only need 1 No More Props or Tight Space unit vs. a number of acrows and strongboys, depending on the size of opening to be made.

If you’re working on upper floors, then the number of acrows required is even higher......but you still only need 1 No More Props or Tight Space unit because there is no need to prop to ground or point load.

|

Size of No More Props or Tight Space Unit |

Small |

Medium |

Large |

|

Equivalent usage of acrow props at ground level |

2 |

4 |

6 |

|

Equivalent usage of strongboys at ground level |

2 |

4 |

6 |

|

Time saving of propping/prepping vs. acrow props |

50% |

50% |

50% |

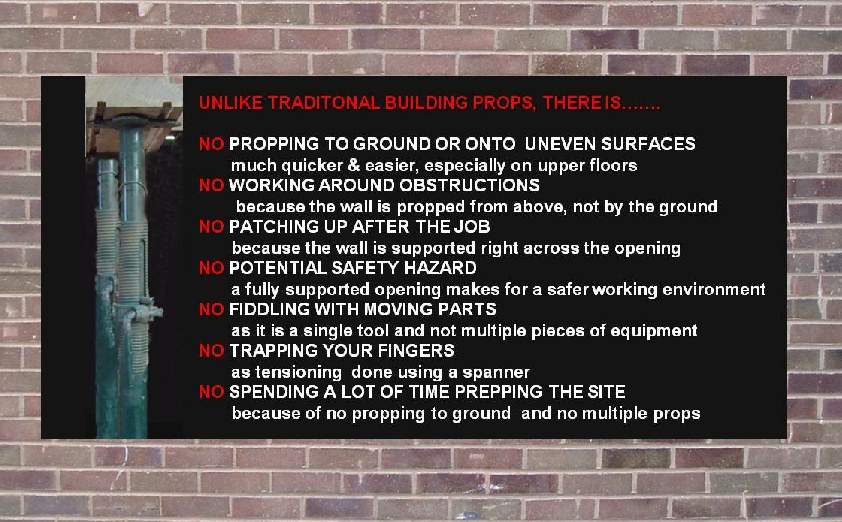

No More Props vs. Acrow Props

When building an extension, or making a new door or window opening, there is the need to knock through into the existing building and install a lintel. This means the builder or the DIYer has to knock a few bricks out to create a hole, which then allows the wall above to be supported using adjustable acrow props - this is a skilled, difficult and lengthy process, but has to be done properly to prevent the wall collapsing.

Up until now, there has been no alternative to using acrows, but these have numerous disadvantages, which No More Props does not.

Firstly, you need quite a few acrow props, along with a needle or strongboy for each, to support the wall from either side. You can end up with a forest of acrows, which stop you putting a steel or concrete lintel in.

If you’re working on an upper floor, then you need even more acrows, in order to prop to ground.

Acrow props are particularly difficult to work around when carrying out work on small openings, such as windows, or in cramped spaces.

And when you’ve done the job, you have to patch up the holes you made to install the acrows and strongboys in the first place.

Acrow props are bulky to store, transport and work with.

They rust and are uncomfortable to handle - trapping fingers between the moving parts is an occupational hazard.........any builder will tell you !

They can present Health & Safety at Work issues with the risk of timber wedges being accidentally knocked out from between the acrow and the stone or brickwork.